If you’re keen to keep things easy then a drip machine or single serve coffee maker keeps hard work to a minimum. This is a very well designed, user-friendly drip machine that has properly earned its space in the most effective, stainless steel drip coffee maker class. These coffee makers normally have stainless-steel bodies—and sometimes components. Such supplies enable the machine to face up to put on and tear better than plastic, which will assist the device last more. The following sections will review the most effective chrome steel espresso makers. I’ll cover each machine’s advantages and downsides, specs, and extra information that can help you decide their worth.

If you’re keen to keep things easy then a drip machine or single serve coffee maker keeps hard work to a minimum. This is a very well designed, user-friendly drip machine that has properly earned its space in the most effective, stainless steel drip coffee maker class. These coffee makers normally have stainless-steel bodies—and sometimes components. Such supplies enable the machine to face up to put on and tear better than plastic, which will assist the device last more. The following sections will review the most effective chrome steel espresso makers. I’ll cover each machine’s advantages and downsides, specs, and extra information that can help you decide their worth.The best coffee maker general for the drip machine class must be the Moccamaster. Recognized by the specialty espresso affiliation as a licensed home brewer this gadget takes espresso making to a different degree. The carafe lid, filter basket, and showerhead are all dishwasher safe so easy to keep clear. The non-stick warming plate has a 40-minute automated shutoff so good for absent-minded folk (like me!). First, Caixa d água cilindrica horizontal and foremost, the high-grade technology built into the Breville Precision Brewer is next degree. It makes use of a super-accurate PID controller to ensure your espresso is brewed at the absolute perfect temperature. It will consistently brew your coffee completely every time.

Are there any water level indicators on the removable reservoirs?

A drip espresso maker brews fresh coffee right into a pot by heating water and distributing it over coffee grounds. This type of coffee maker is superb for households or workplaces due to its ability to produce a number of servings simultaneously. A drip coffee maker automates the process of brewing coffee by heating water and dripping it by way of a basket of grounds into a carafe. It’s good for those looking for consistent, hassle-free coffee at home or work. The lack of cup measurement choice and water dispenser makes me weary about recommending this Nespresso.

(e) A reflux drum to carry the condensed vapor from the top of the column in order that liquid (reflux) may be recycled again to the column. The most widely utilized trays in course of industries are 1. Structured packing is fashioned from corrugated sheets of perforated embossed metallic or wire gauze. The result is a very open honeycomb structure with inclined flow channels giving a relatively excessive floor space however with very low resistance to fuel move. It will take roughly two minutes to see the condensate moving in the reboiler (HX101) resulting to 15psig pressure. Tank-Mart.Com is proud to be America's largest provider and distributor of plastic storage tanks, together with low profile holding tanks, custom water storage tanks, and more.

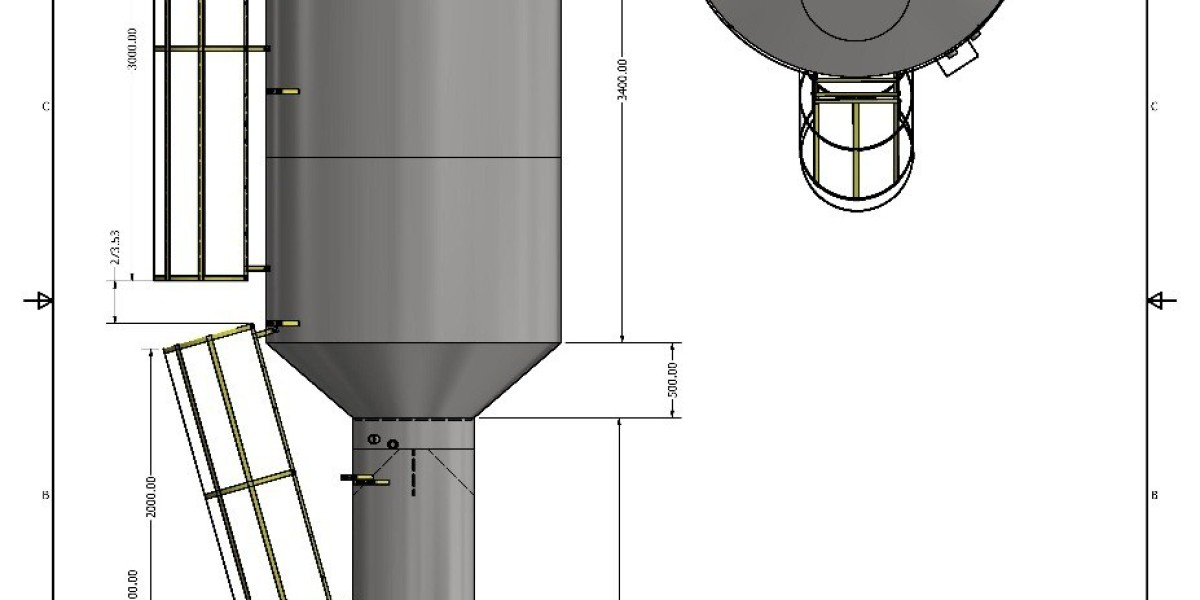

Distillation Column Components

As the vapor price increases, the valve lifts, and the open space for vapor flow additionally will increase. In basic, distillation trays are used for purposes with liquid rates of 30 m3/m2-h and above, and/or these the place solids are present or fouling is a priority. Trays are designed to supply liquid holdup (stepwise contact) to attain the proper vapor-liquid mass switch that the distillation process requires for separation. Since the valve tends to shut because the gas circulate turns into decrease, the whole orifice space varies to maintain up a dynamic-pressure balance across the plate. Because of their flexibility and affordable worth, valve trays tend to exchange the bubble-cap trays.

New pressure drop correlation for sieve tray distillation. For the ethanol-water separation represented in Figure 2.5, if the data have been collected from a column with seven phases, what's the general column efficiency? Some of the best designs are spray columns with out internals and packed columns containing randomly crammed and stacked packing parts, tube columns or columns with structured packing, see Fig. The valve plate is designed to minimize this drainage, or "weeping," because the valve tends to shut because the gas flow becomes lower, the entire orifice space varying to maintain up a dynamic-pressure balance throughout the plate. If you’re in want of a heavy-duty water truck, you must place your belief in Curry Supply – the main producer of water vehicles and water tanks for trucks.

Types of Distillation Column Internals

Increasing downcomer top width is a regular technique to handle choking problems. It lowers the top froth velocity, permitting improved vapor disengagement. The secret is to make use of a balanced design to deal with each the liquid and vapor loads throughout the column. Apart from totally different column internals, tray column and packed column have related format for exterior circulate arrangement.

Which is Better – Tray Distillation Columns or Packed Columns?

Because of the CMO assumption, both liquid and vapour move charges stay fixed throughout the tray. As nicely, the vapour leaving the tray with composition $ y_n $ is taken into account to be in equilibrium with liquid leaving the tray with composition $ x_n $. The plate distillation column stands at a top of __ and a diameter of eleven.87 inches. There are 12 plates in the column where, from the bottom-up, there are four sieve trays, 4 ballast trays, and 4 bubble-cap trays. A pump is used to feed the streams into the column and there are pumps at the condenser and reboiler (to overcome head loss).