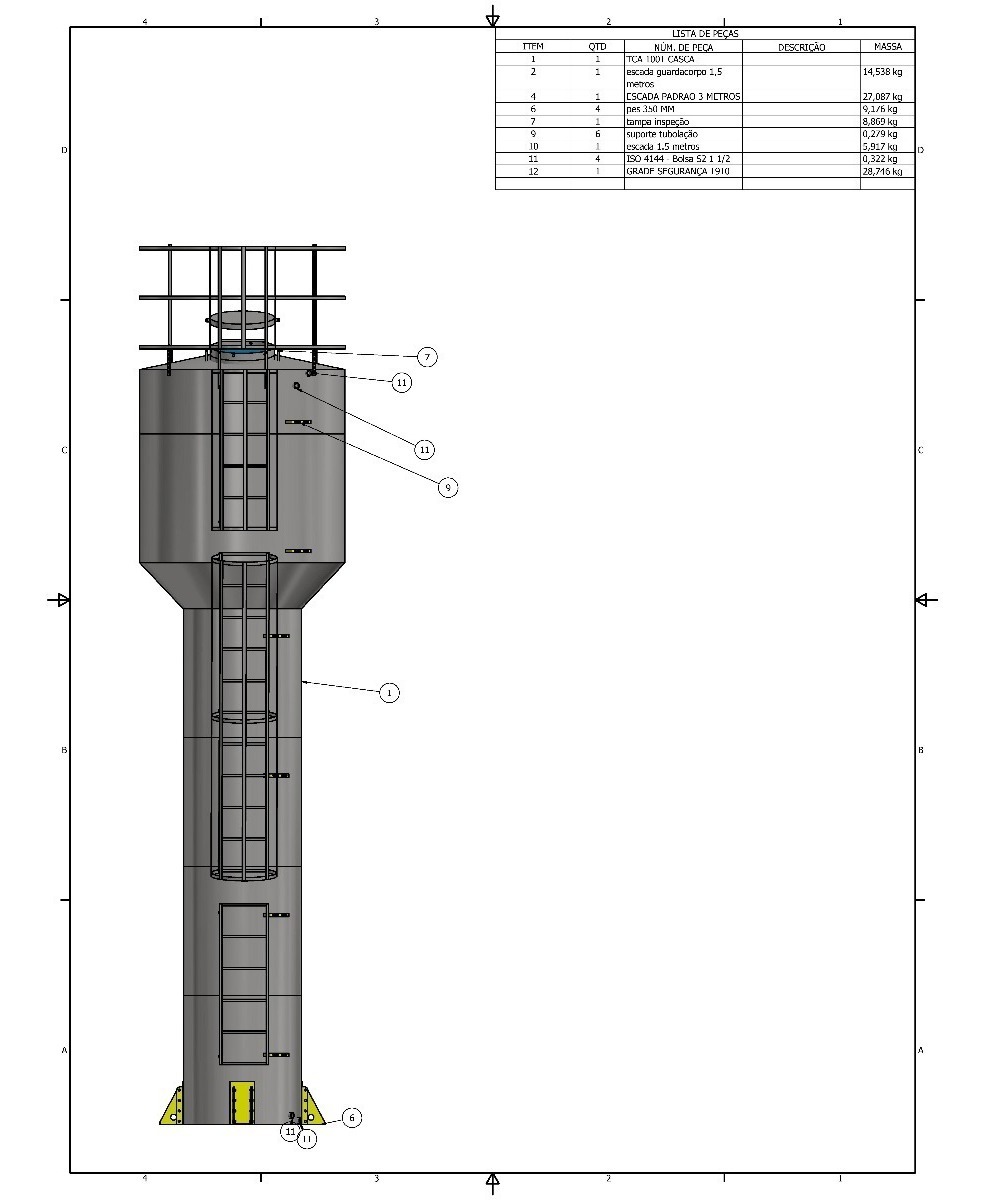

Under evaluation, the total put in costs (material + freight + subject installation) are comparable between both merchandise. This eliminates the shop-weld tank, until we break the capacity necessities into a two tank bundle. This doesn't imply we specify a silo designed for mass flow design hundreds. The right request is to specify a storage silo designed for functional mass flow discharge. In order to supply dependable "practical mass flow" (FIFO) discharge, the material will have to be tested.

Since 1986, Aquamate has designed, manufactured and put in thousands of Poly Lined Steel Water Tanks in sizes from 5,000 to 200,000 Gallons. With greater than 30 years of analysis and development, an Aquamate steel water tank is the first selection for Durable, Reliable and Affordable massive quantity water storage. Our metal water tanks have three main purposes – rainwater storage, fire suppression water storage, and nicely water storage. Our plastic water tanks manufactured from WRAS accredited material are DWI permitted and meet the precise requirements of Regulation 31.

The major distinction of fluted columns is their construction completely of carbon steel. The "high 10" list beneath contains primary considerations that must be addressed on each storage application. If the appliance under evaluation is routine and no downside areas exist with the product/liquid saved, a normal storage tank quotation could be generated. If any objects listed are a priority, a specialist in storage functions ought to advise you on the correct approach. These bolted RTP limestone storage silos function kiln feed storage for cement manufacturing. This cutting-edge facility consists of (6) 2000 MT silos with a complete working storage capability of eight,000 cubic meters. Unique to this facility is the assist for each rail and truck materials receiving.

The major distinction of fluted columns is their construction completely of carbon steel. The "high 10" list beneath contains primary considerations that must be addressed on each storage application. If the appliance under evaluation is routine and no downside areas exist with the product/liquid saved, a normal storage tank quotation could be generated. If any objects listed are a priority, a specialist in storage functions ought to advise you on the correct approach. These bolted RTP limestone storage silos function kiln feed storage for cement manufacturing. This cutting-edge facility consists of (6) 2000 MT silos with a complete working storage capability of eight,000 cubic meters. Unique to this facility is the assist for each rail and truck materials receiving.The APEX Domes Advantage Kansas Water Treatment Facility

With the basics covered, the selection process can be narrowed for buyer evaluation and desire. Caldwell offered 41 Field Erected, Steel Welded Tanks to empower Sasol Chemicals' vision, creating a extensive range of tank sizes and types, made out of different materials. Tank Connection's state-of-the-art, corrosion resistant aluminum domes are virtually upkeep free and backed by a two-year warranty. Our domes are all-aluminum with proprietary design and elements, superior aesthetics, and unmatched efficiency. Tank Connection's Bolted RTP silo serves because the centerpiece of this large cement terminal facility in Melbourne, Australia.

Aluminum Domes (Spanish)

All storage tanks and storage silos are personalized for the application and can be found for installation at grade level or elevated. In summary, if the fundamentals are covered in storage tank choice, years of bother free containment can be expected. In right now's industrial and municipal storage markets, a storage specialist ought to advise or affirm your selection. In all circumstances, a reliable storage tank system begins with a properly designed and configured tank/silo.

Tank Connection development crews put in this Barge-to-Truck transloading terminal with a 127’ tall by 41.5’ diameter RTP bolted Cement Storage Silo to retailer and transfer cement from ocean barges. Tank Connection also designed, provided and put in the pneumatic conveying piping and the unloading system. Tank Connection’s bolted RTP (Rolled, Tapered, Panel) silos feature dependable product circulate, and remarkable coating toughness. Bolted RTP designs present the freedom of various configuration and accent choices. Headquartered in Louisville, KY, Caldwell Tanks, Inc. has been building progressive, personalized water and industrial storage tanks & vessels throughout North America since 1887. Easily find the dry bulk hopper capacity you require for your bolted RTP, XL bolted RTP or store weld project. The scales are decided by diameter, eave hight, forty five diploma hopper working capacity and 60 degree hopper working capacity.

Tank Connection is the leading bolted tank manufacturer for manufacturing unit coated bolted storage tanks and aluminum bulk storage covers for dry bulk storage applications. Tank Connection dry bulk storage solutions embody superior engineered tank, hopper and aluminum cowl designs, unmatched coating technology, and golden rule of customer support. Tank Connection is a quantity one world storage tank producer for liquid and dry bulk storage applications. We are the one storage tank manufacturer worldwide that designs, fabricates and caixa d água tipo taça 10000 Litros preço installs all 4 main forms of steel storage tanks. Bolted storage tanks, field-welded storage tanks, concrete storage tanks and hybrid storage tanks are usually utilized in giant quantity storage functions.

Tank Connection Proprietary Storage Tank Coating System